In order to stay competitive in the demanding aftermarket segment that is performance engine building, manufacturers have to keep increasing their capabilities–and Ferrea is no stranger to those demands. When we talk about manufacturing capabilities, we mean a whole portfolio of skills and knowledge. From the very beginning, it requires communication to best understand the needs of a custom order or application. Then moving on to design and engineering, before finally going into production.

Whether this process nets tens of thousands of valves for an OEM application or a single set for an exotic engine, throughout the process it takes an understanding of materials, science, and the demands of the end user. When all these skills come together, a manufacturer can develop solutions to problems in short time frames.

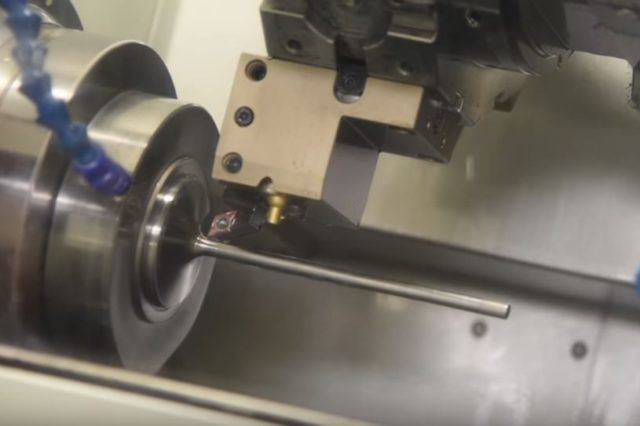

CNC machining centers allow Ferrea to create custom parts for all sorts of applications. Here wee see a valve being shaped on a lathe.

In this video, Ferrea Racing shows us some of the facets of their business that have kept them a mainstay brand when it comes to valvetrain components. With production kept in-house in the USA, and an emphasis on the custom side of production, Ferrea is able to pioneer new solutions and go through the testing required to verify their designs will perform in the real world.

Testing and verification is an important part in developing new parts. In the video we see destructive tensile strength testing alongside conventional quality control and flow-bench testing. If you have a custom application for valves, give Ferrea Racing a call and explain your needs. Chances are their development program can provide a solution to your problem.