The LT4 engine is the most powerful V8 that General Motors has ever put together for sale in an automobile, and in this slick video from Speed Academy we get the opportunity to go inside the Tonawanda, New York engine plant where the LT4 powerplants come to life.

The sprawling facility builds not only the LT4, but also four- and six-cylinder engines. The video discusses some of the tricks that GM uses to track the engine parts as they travel down the production line, such as the use of Radio Frequency ID chips implanted into bolts installed into the block castings. These bolts, installed into the side of the block and easily visible to the tracking scanners, permit the computer tracking system to monitor each step of the machining and assembly process to enhance quality control.

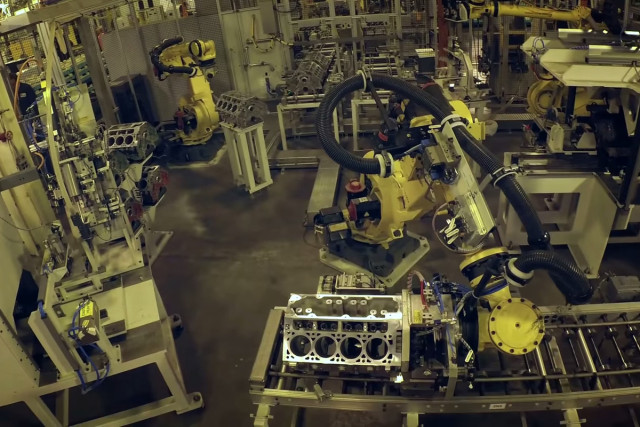

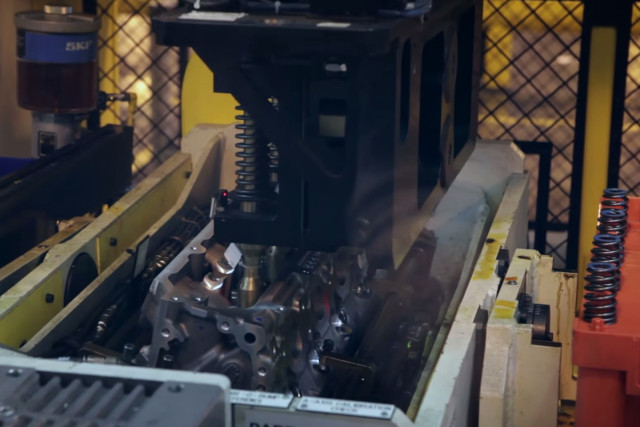

It’s impressive to watch the level of robotic testing and control that goes into the block machining process before it ever reaches the assembly line, with multiple cameras and measuring devices employed to track specifications down to the micron.

Robotic processes continue throughout the build sequence, as the cylinder heads are completely assembled by robots, with line workers checking some of the specifics to ensure quality control.

Robotic processes continue throughout the build sequence, as the cylinder heads are completely assembled by robots, with line workers checking some of the specifics to ensure quality control.

Once engine assembly begins, it’s a whirlwind of activity on the line, with line workers using heavy machinery to finish off the engine. The specific needs of the direct-injection system require extra testing to be done on the fuel system, with leak detection and cold testing chief among the processes handled at this time, before engine assembly is completed, more testing is done, and the engine is shipped off to Bowling Green to be mated with its chassis.

The entire video is over eleven minutes long, but it’s well worth the watch to get an inside look at how the high-power LT4 comes to life. Check it out!